High Performance Fiber Bed Filter

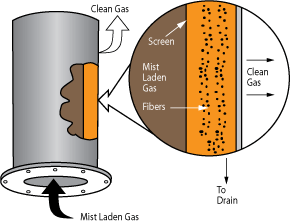

Many industrial, chemical, and food processing applications generate sub-micron mists. The Monroe Fiber Bed Oil Mist Collector, developed after lengthy research and testing, is an ideal solution for these troublesome mists. Mist particles are efficiently removed through interception, inertial impact, diffusion (Brownian movement) and gravitational sedimentation.

The Monroe Fiber Bed Oil Mist Collector removes particles as fine as 0.3 micron. While normal filters permit these particles to re-entrain into the outgoing clean air, Monroe’s self-draining filter is designed to prevent oil re-entrainment and recirculate clean air to the atmosphere.

Monroe carefully selects fiber bed filters to give constant efficiencies as high as 99.99% on all mist particles.

Fiber Bed Oil Mist Collectors: The Monroe Advantage

The Monroe Fiber Bed Oil Mist Collector design provides the following advantages and benefits:

-

Heavy gauge steel is used for most installations, but special construction materials are available to meet specific applications. Welded seams and built-in lifting hooks provide rugged durability.

-

Large easy to open access doors, each with air-tight seals, for all serviceable areas.

-

An AMCA rated fan on the outlet side of the collector with either a direct coupled motor or a “V” belt drive.

-

Quiet operation. Flexible duct connections, fan mounting isolators, sound attenuators and fan enclosures are available.

-

Integral pressure gauges are available to indicate when filter maintenance is required.

-

Complete electrical controls to meet customer requirements are available.

System Design — Fiber Bed Collector

The Monroe Fiber Bed Oil Mist Collector is available in capacities from 500 to 50,000 CFM in a single unit and may be integrated with existing duct work.

The Monroe Fiber Bed Oil Mist Collector is well suited for many oil mist applications including high production machining, asphalt fumes and synthetic fiber processing.

Custom Built Fiber Bed Units

For special applications, when mist is generated at high temperatures, Monroe provides custom designed condensing heat exchangers. Gas to air or gas to water heat exchangers are offered, depending upon application.

Multi-Stage Compact Units

For heavy duty operations where the mist is dirty or dust-laden, or when large oil droplets exist, Monroe provides multi-stage filtration with various pre-filtering elements followed by the fiber bed filters.

Filtration Efficiency

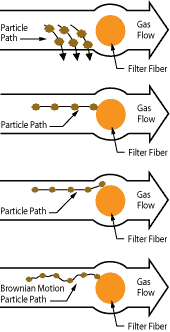

The mist particles in the Monroe Fiber Bed Oil Mist Collector are deposited on the filter in four ways:

- Gravitational sedimentation occurs for heavier particles or droplets in the first stage and for coalesced droplets in the final stage.

- Inertial impaction. Particles are unable to adjust quickly enough to the abruptly changing streamlines in the vicinity of fibers (greater than 3 microns).

- Interception. Particles follow a gas stream line that comes within one particle radius of the surface of the fiber (1 to 3 microns).

- Diffusion or Brownian movement greatly enhances the submicron particles tendency to attach themselves to fibers due to their random movement (less than 1 micron).